Compounding staff are sufficiently experienced, educated, instructed, and properly trained to correctly accomplish and document the next routines within their sterile compounding responsibilities: Conduct antiseptic hand cleansing and disinfection of nonsterile compounding surfaces; Decide on and properly don protective gloves, goggles, gowns, masks, and hair and shoe handles; Use laminar stream thoroughly clean-air hoods, barrier isolators, together with other contamination Command products that happen to be suitable for the danger level; Discover, weigh, and measure elements; and Manipulate sterile products and solutions aseptically, sterilize superior-chance level CSPs, and label and excellent inspect CSPs. Ingredients have their appropriate identification, excellent, and purity. Opened or partially used offers of elements for subsequent use in CSPs are effectively saved below limited entry circumstances in the compounding facility. This kind of packages can't be employed when visual inspection detects unauthorized breaks inside the container, closure, and seal; if the contents don't have the predicted visual appeal, aroma, and texture; if the contents will not go identification tests specified through the compounding facility; and when both the over and above-use or expiration day is exceeded. To attenuate the era of bacterial endotoxins, drinking water-that contains CSPs that happen to be nonsterile in the course of any section in the compounding process are sterilized within six hours after completing the preparation.

Personnel getting into the buffer or cleanse space should initially scrub hands and arms with cleaning soap, which includes employing a scrub brush to the fingers and nails. An air dryer or disposable nonshedding towels are accustomed to dry fingers and arms following washing.

The nature of the crucial internet site also affects the chance of contamination. The comparatively rough, permeable area of an elastomeric closure retains microorganisms and also other contaminants, after swabbing by having an alcohol pad, more easily than does The sleek glass surface area with the neck of an ampul. Thus, the surface disinfection is usually anticipated to get more effective for an ampul.

Units might be incubated upright when they are already inverted to wet al inner surfaces with media. Media might also be incubated inverted.

Cleaning and Sanitizing the Workspaces The cleansing, sanitizing, and Arranging of the immediate and contiguous compounding locations (DCCA) could be the responsibility of properly trained operators (pharmacists and professionals) following composed processes and is carried out firstly of each and every shift. Just before compounding is executed, all objects are faraway from the DCCA and all surfaces are cleaned of loose product and residue from spills, followed by an software of the residue-no cost sanitizing agent2 that may be left on to get a time ample to exert its antimicrobial influence.

These chance stages apply to the quality of CSPs immediately following the ultimate aseptic mixing or filling or immediately following the closing sterilization, Except if precluded by the precise features from the preparation, including mediafill test in sterile manufacturing lipid-centered emulsions the place administration should be concluded within twelve several hours of planning. On subsequent storage and delivery of freshly completed CSPs, a rise in the pitfalls of chemical degradation of components, contamination from physical damage to packaging, and permeability of plastic and elastomeric packaging is expected.

Utilize a vial of media to simulate the diluent you may add to a part. Diluting the media with sterile h2o, will render it much too dilute to aid microbial progress.

A essential web site is any opening providing a direct pathway check here involving a sterile item as well as setting or any area coming in direct connection with the product or service along with the ecosystem. The risk of this kind of web site choosing up contamination from your setting raises with time of exposure.

Inspection shall be carried out by experienced microbiologists or staff skilled by certified microbiologists to acknowledge contaminated media filled containers.

USE and STORAGE The pharmacy is liable for guaranteeing that CSPs from the client-care setting keep their top quality until finally administered. The immediate labeling with the CSP container will Show prominently and understandably the necessities for appropriate storage and expiration relationship.

for the appropriate security parameters for being considered when initiating or assessing a product-unique steadiness review.

Il est impératif de définir la conduite des MFT en s’entourant de personnes expertes dans ces domaines avec une huge expérience des retours de l’industrie.

This process verification gives evidence of whether or not the ACD will be able to make sterile parenteral diet. Accomplishing system verification is just not a need of Chapter having said that undertaking system verification of new or intricate processes is often a encouraged ideal practice. If you carry out course of action verification, then the individual undertaking this course of action would, in effect, be verifying their aseptic method (visualize the many aseptic connections this person is producing) though They're managing the process verification.

Use Pharmacopeia specified expansion advertising organisms in addition to agent organisms discovered throughout environmental checking.

Robert Downey Jr. Then & Now!

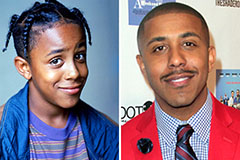

Robert Downey Jr. Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!